SPluscomtech is a company dedicated to the research, development, and manufacturing of advanced composite materials. By leveraging next-generation materials such as carbon fiber, sgr/sgm(Shaft Grounding Rings/Modules), graphene, aramid fiber, and glass fiber, our composites deliver superior performance—offering lightweight design, durability, conductivity, heat dissipation, and thermal resistance. These innovations provide not only effective and economical solutions but also contribute to a more sustainable and eco-friendly future.

Introduction

S PLUS COMTECH CO.,LTD.

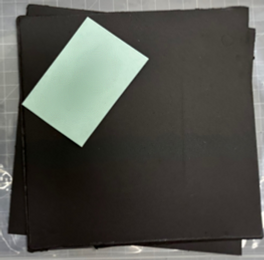

Battery Thermal Runaway Delay Nonwoven Sheet (Flame-Retardant / Insulating / Heat-Resistant Sheet)

Designed to fit between EV battery cells, this lightweight, elastic pad absorbs impact under normal conditions. It offers excellent flame resistance and insulation at high temperatures, helping to prevent thermal runaway propagation. The pad can withstand over 1200°C for 5 minutes without burning or melting, while keeping the opposite side around 300°C, providing superior thermal insulation.

Purpose and Necessity of Thermal Runaway Delay Foam/Pad

Vehicle Battery Thermal Runaway Delay Foam/Sheet

•Major causes of EV fires are battery impact or overcharging.

•Thermal runaway during EV battery fires makes suppression difficult due to rapid temperature rise.

•Increasing battery capacity and quantity is needed to improve EV range.

•Safety measures are required to delay thermal runaway in automotive batteries.

•Can be applied to various areas requiring insulation and flame resistance.

Structure and Types of Thermal Runaway Delay Foam/Pad

•The foam/pad consists of sections for thermal protection (flame-retardant) and elasticity.

•Various inorganic materials can be used depending on the required thermal barrier temperature.

Thermal Runaway Delay Foam/Pad – Flame Test Video & Specifications

Flame Test Results

The foam/pad maintained its integrity for over 5 minutes at temperatures above 1200°C, while the opposite side remained around 300°C, showing a temperature difference of over 900°C between the front and back.